SERVICES

Petrorix Oil and Gas is well known for diversity in various oil and gas services. Our services span across engineering, procurement of all kinds of equipment for well-development offshore and on-shore, constructions and Installation.

Engineering

Our engineering team comprises of well-seasoned and top notch professionals in their various fields of operations, providing articulate delivery of projects. To achieve efficiency and effectiveness without compromising quality, we have put in place several measures in the area of operational cost reduction, safety and productivity enhancement. With over 60 years of collective experience on board, we are driven to provide excellent services to our customers.

Procurement

Through our strongly established relationship with Original Equipment Manufacturers (OEM) who are enlisted in the Approved Manufacturers List (AML), we are committed to the supply and delivery of world class oil industry products and equipment. We provide the best products/equipment at the best prices for our customers both locally and internationally. We have a solid business relationship with some of the best equipment suppliers all over the continent in a bid to provide the best for our clients.

Our procurement products include but not limited to:

– Pipeline Accessories (Seamless line pipes, piling sheets, pipe fittings, etc)

– Instrumentation and Flow control products.

– Standard Welding Equipment.

– Rotating Equipment (Pumps and Compressors).

– Welding Consumables and accessories.

– Personal Protective Equipment.

– Deck equipment, Lifting Equipment, Floating fenders, etc.

– Test instrument and oil tools.

Our experience in the oil and gas industry has set us apart to perfectly execute projects in engineering, construction and installation.

Our services in this areas include but are not limited to:

– Mechanical/ structural Designs

– Facility Engineering

– Subsea Engineering

– Corrosion and Anti corrosion services

– Well head construction and completion.

– Pipeline/ flowline construction

– Installation of heavy equipment

– Piping installation

Storage Tanks

At Petrorix Oil and Gas, we also supply, install and maintain Tanks such as: Fixed roof tank, Floating roof tank (FR and IFR tanks), pressure vessels and other storage tanks used in the oil and gas industry. We work with your tank specifications to deliver cost-effective, long lasting and quality storage tanks for maximum productivity. Customer satisfaction is our top priority.

Hazard Identification and Assessment (HAZID)

At Petrorix, we possess in depth understanding and wide range of experiences conducting Hazard identification in high-risk environment. HAZID is the first and most crucial step in conducting a qualitative, semi quantitative or quantitative risk assessment. It is a qualitative review of plants processes, procedure and systems that are capable of causing harm.

Identified hazards will vary depending on the type of plant, structure and lifecycle stages of activities to be considered. Petrorix utilizes various techniques such as Hazard Review, Hazard and Operability Study (HAZOP), Procedural HAZOP, HAZID and Emergency System Survivability Analysis (ESSA) for Hazard Identification and Assessment:

Quantitative Risk Assessment (QRA)

Quantitative Risk Assessment is often used in major accident hazard facilities such as Offshore Installations, Refineries and LNG Plants

It is a form of risk assessment executed by specialists to demonstrate acceptable risk levels from identified hazardous event to individuals, employees, the environment and the business as a whole. A Quantitative Risk Assessment includes the identification of potential hazardous event together with an estimate of the likelihood and the consequences of the hazardous event occurring. The result is presented as risk to people, environment and business.

At Petrorix, we work closely with our clients, offering our professional expertise in undertaking their QRA studies, identifying the top risk contributors on their facility with the aim of providing further risk reduction measures in order to meet the risk acceptability criteria defined by either local regulations or company policy.

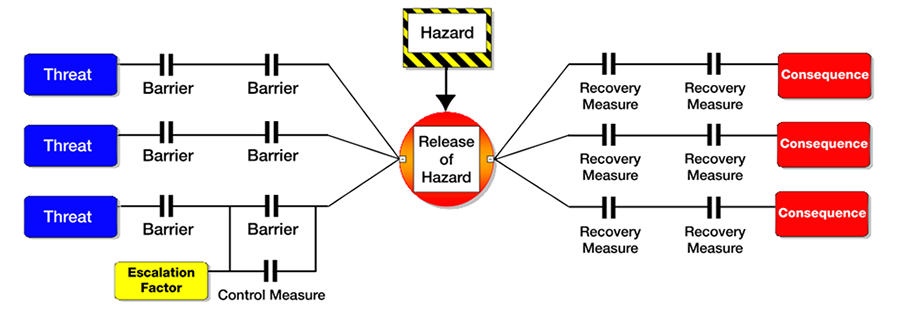

Bow Tie Risk Assessment

The BowTie methodology is used for risk assessment, risk management and (very important) risk communication. The method is designed to give a better overview of the situation in which certain risks are present; to help people understand the relationship between the risks and organizational events. The strength of the methodology lies in its simplicity; the phrase ‘less is more’ is certainly applicable. Risk in BowTie methodology is elaborated by the relationship between Hazard, Top Events, Threats and Consequences. Controls are used to display what measures an organization has in place to control the risk. Petrorix consultants are trained and competent in carrying out Bowtie risk assessment for our clients. The Bowtie risk assessment enables them to have a complete and thorough understanding of the hazards they are exposed to, its consequences, together with the effectiveness of the prevention and mitigating barriers that have been put in place to prevent the occurrence of the hazard.

Safety Case Development and Management

At Petrorix, we specialize in the development of safety cases for new installation, review and update of safety case for existing installation either as a result of extensive modification to the installation or due to legislative requirement. We work closely with our clients to ensure that their installation risk management system in terms of overall estimation of risks and the safety management system required to reduce this risks to tolerable levels are adequately documented. Fire, Explosion and Gas Dispersion Modelling and Analysis Petrorix offers physical effect modelling services, and assist clients to identify cost effective mitigation strategy necessary to reduce the impact of hazardous events.

We use industry recognized consequence modelling so ware tools to undertake:

– Fire Risk Analysis

– Explosion Risk Analysis

– Flammable Gas, Smoke and Toxic Gas Dispersion

– Analysis Escape, Evacuation and Rescue Analysis

Environmental Services

Petrorix provide services in the areas of:

– Maintenance, Installation and audit of Safety related equipment.

– Environmental Impact Assessment Development.

– Safety Management System Audit using industry standards and best practice.

– Development of Oil spill contingency plan Behavioral Based Safety

– Environmental Audit

– Impact mitigation monitoring

– Biodiversity Studies

Other Formal Safety Studies

At Petrorix, we offer a variety of individual safety studies using industry widely accepted software modelling tools where appropriate for:

– Gas/Flare Dispersion Analysis

– Major Accident Hazard Risk Assessment

– Summary of Operational Boundaries

– Fire and Explosion Analysis

– Hazardous Areas Classification

– Dropped Object Studies

– Fire & Gas Optimization Layout

Asset Assurance

At Petrorix we offer Inspection and Verification services for all stages of a platform’s, Rig and Vessel life-cycle to ensure that the integrity of the asset is retained. Our Services include the Identification of safety critical elements (SCE), development of performance standards, inspection and maintenance schedule for identified safety critical elements (SCE), Layer of protection analysis, Development of framework for identifying, recording and tracking safety critical faults and verification.

Risk Based Inspection

Risk-based inspection (RBI) is the process of developing an inspection plan based on knowledge of the risk of failure of equipment. Petrorix offers RBI solutions to Members as part of its risk and reliability engineering services. Our exhaustive knowledge of materials degradation processes, and demonstrable track record in this area, mean Member companies can rely on us to develop the right plan for each scenario. Using an established methodology and Petrorix bespoke so ware, we can develop maintenance or replacement solutions, giving guidance on managing your assets in the most effective manner, from individual component studies through to turnkey, plant-wide projects – tailored to your needs. Our asset integrity management and plant life assessment services work together to maximize the reliability and efficiency of a structure or component.

Petrorix has recently developed quantitative data trending as a means of mitigating risk in equipment where reliable data is scarce or unavailable. This, coupled with Petrorix so ware (API 581 compliant) allows assessments to be conducted with greater speed and accuracy than ever before.

Inspection, Verification and Compliance (PSSR)

Petrorix provide 3rd party independent verification and inspection services for oil and gas assets from Plants, FPSO, Rigs, Platforms, etc. Our Commissioning and Verification work determines that a piece of equipment will perform as expected in operation. We ensure that construction and installation is carried out to international regulatory standards with expertise to assure our clients that performance and acceptance standards are met. We have qualified safety engineers and Verification engineers who can carry out pre startup safety reviews during project life cycle phase.

Asset Integrity Management

Asset Integrity Management means a management system which plant owners use to ensure that the people, systems, processes and resources, which deliver the Integrity, are in place, in use and fit for purpose over the whole lifecycle of the asset. They are therefore essentially Risk Management activities forming the basis of inspection and safety, the creation, planning and execution of procedures covering inspections/tests and the activities supporting this, such as recording inspections and corrective action. Additionally, it also covers production system components which are not SCE’s but which must be maintained fit-for-purpose.

Pipeline & Structural Engineering

We offer and provide expert knowledge and solutions in Pipeline & Structural Engineering in order to complement all requirements relating to asset management. The following services are offered:

– Pipeline Integrity Management System (PIMS) development

– Corrosion Engineering and Management services

– Integrity management plans

– Fitness for service assessments

– Life extension studies

– Assessment of in-line inspection results

– Pipeline uprating and De-rating studies

– Failure investigation

– Cathodic Protection (CP) Design

– Pipeline and Riser Coatings Design and Selection

– Field Joint Coatings Design and Selection

– Internal Pipeline Coatings/Linings

– Pipeline Design Engineering

– Pipeline Welding & NDT Services

Flexible Pipe and Riser Integrity

Maintaining the integrity of flexible pipe field system requires a systematic approach towards ensuring pipe integrity over the entire field life. Our management system is designed to provide an efficient and effective means of managing the safe operation of the flexible pipe and of ensuring compliance with legislation, corporate expectations, best industry practice and business requirements.

Petrorix provides a quality integrity management system, which utilizes the correct mix of inspection and assessment tools and procedures to access the level of risk in flexible pipe systems and also the potential for life extension and re-use. At Petrorix, a structured risk-based approach to the integrity management of flexible pipe field systems is used to provide us the confidence to manage our client’s flexible pipe integrity performance.

The following services are offered:

– Flexible Pipe Integrity Management System (FPIMS) development

– Asset Management Strategy Development & Implementation,

– Life extension of flexible pipe system,

– Assessment of flexible pipe re-use and use in specific environment,

– Preventative Maintenance Optimization,

– Criticality and Root Cause Analysis,

– Design & Supply of Polymer Monitoring Spares & Accessories, and

– Polymer Coupon Retrieval, Aging Testing and Performance Assessment.

Structural Integrity Management

Petrorix support customers in maintaining their structural assets and offer a value-added structural integrity management services for fixed and floating structures. With our advanced assessment capabilities, operating experience of routine and emergency response situations, and state of art so ware capability, we can provide our customers with the following structural integrity management service.

– Structural Condition Monitoring

– Integrity, Inspection strategies

– Structural Defect Assessment

– Loading analysis and weight control programs

– Structural life extension studies

– Consultancy service

Project Management

Our Project management services cover every stage of a project from inception to completion. Petrorix acts on behalf of clients in every area, integrity management operations; contract tendering, evaluation, and execution management; fabrication monitoring; process facilities commissioning; management of offshore installations (platforms, facilities, pipelines); platform refurbishments and upgrades; management of platform abandonment and salvages.

At Petrorix our strategy is focused on efficient enactment and a high degree of technical competence at all levels within the project team. This allows the disciplined experts the opportunity to deliver technical excellence whilst maximizing the efficient use of key resources in a safe and cost effective manner.

Wellhead Solutions

At Petrorix Oil and Gas, we have years of experience in procurement, installation and maintenance of equipment needed in the oil and gas industry. Some of the heavy-duty equipment are Wellhead and Tanks. With highly trained technicians, we perform wellhead maintenance service that defines risk assessments while maintaining the safety regulations standards. Our services with wellheads extend to leak detections and repairs. Due to our versatility and in depth understanding of the types of wellhead and wellhead equipment, we also major in the supply of wellhead equipment.

Our Wellhead maintenance services include but are not limited to:

– Non-Destructive Testing (NDT).

– Visual Inspection.

– Pressure testing of Valves.

– Pressure bleeding and monitoring.

– Lubrication and testing of Inflow.

Our Wellhead Procurement and supply services deal with:

– The supply of wellhead components such as: wellhead jacket, wellhead valves, casing head, tubing head and tree cap, wellhead tools, surface manifolds and other wellhead accessories.

– Supply and installation of the various types of wellhead such as: Christmas Tree, Conventional Wellhead, Integral wellhead, Dual tubing well head, Multibowl wellhead, ESP wellhead, Frac Tree and the likes.

MANPOWER DEVELOPMENT AND TRAINING

Petrorix recognizes the competency challenges facing the industry particularly across Personnel Management. That is why one of our key offerings is the delivery of high quality training packages. We provide structured training in the areas of:

– HSE Training such as Bowtie Risk Management and HSE Safety Case Development

– Drilling/well engineering related training

– Reservoir Management

– Procurement related training

– Wire and logging training

– Asset Integrity and Management Services

– Other oilfield related training.

Petrorix support customers in maintaining their oil and gas wells and offer a value-added well integrity management services for new and existing onshore and offshore production, gas injection and water injection wells. With our advanced assessment capabilities, operating experience of routine and emergency response situations, and state of art software capability, we can provide our customers with the following well integrity management services:

– Development of Well Integrity Management System (WIMS)

– Risk Based Assessment and Inspection Planning

– Well Integrity Database

– Corrosion Management Services

– Well operational Support Services

– Well Management Resource

DRILLINGS AND COMPLETIONS

Petrorix is known for outstanding services in drilling and completions in the oil and gas industry. We have a team of highly experienced personnel with vast knowledge of the technicalities accrued to the field. Our services are targeted at fast-tracking completion, promoting efficiency and effectiveness while being cost effective.

Our services span across horizontal and directional drilling, multilateral drilling, extended reach drilling, drilling fluids, well control, bit technology, sand control, cementing and a host of others. We pride ourselves in the quick adoption of technological advancements for further improvement of our services.

We use high technology drilling equipment such as the Rotary Steerable System which improves safety and drilling efficiency.

TECHNICAL DUE DILIGENCE

Investors and private equity firms looking at investing in Oil and gas assets like Rigs, Vessels, FPSO etc. can rely on Petrorix to provide independent Inspection, Audit and Verification service and provide the necessary report and advise if the assets are fit for purpose. Our consultants have in the past provided technical due diligence and verification service on oil and gas assets and continue to do so. High risk generates high returns but in the Oil and Gas value chain low operational risk generates good returns and we help our clients achieve this.

We cover this following areas:

– Inspection and management of Vessels.

– Inspection and Management of Rigs.

– Valuation of Oil and Gas Asset such as Vessels and Rigs